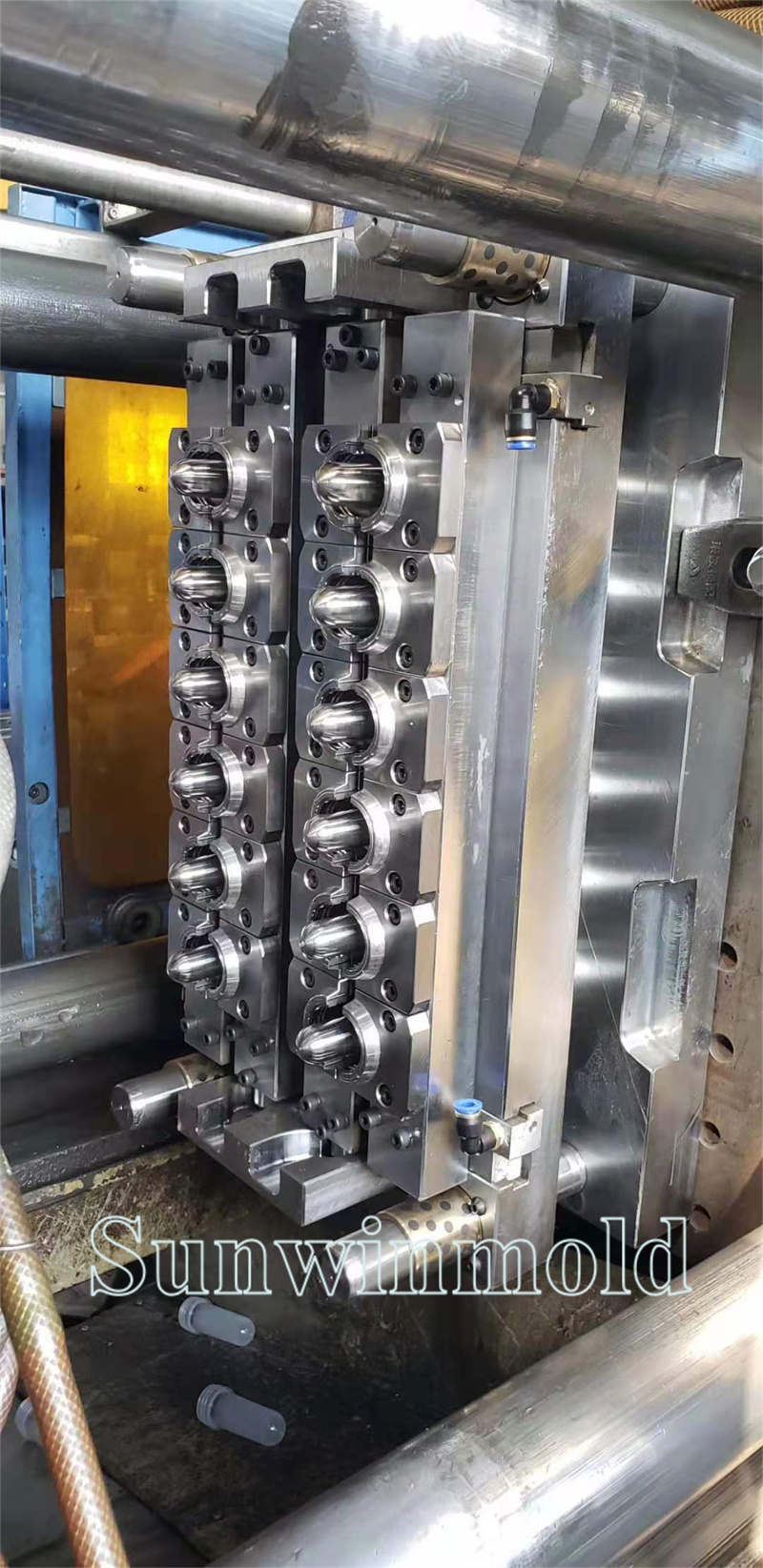

24 Cavity PET Preform Mold

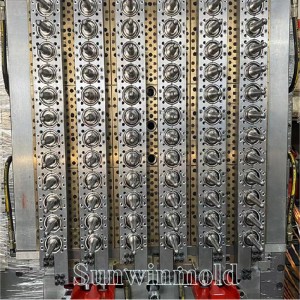

I-48-Cavity Pin Valve PET Preform Mold

1. Umgijimi oshisayo wamukela uhlelo lokulawula lwe-PID, olubonakala ngokulungisa okuzenzakalelayo kanye nemisebenzi yokuvikela okuzenzakalelayo, engandisa impilo yesevisi yedivayisi yokushisa kagesi;

-Izinga lokushisa lilawulwa ngaphakathi kwe-1 ° C ukuze kuqinisekiswe ukuthi izinto zokusetshenziswa azishiswa kumgijimi oshisayo, futhi izinga lomkhiqizo oqediwe lingafinyelela ngaphezu kwama-99%;

-Idizayini entsha yombhobho yenza isikhunta sigcineke kalula, ingxenye yethiphu yenozi, ingxenye yokushisisa, ingxenye yokufaka ukushisa, kanye ne-thermocouple ingashintshwa kalula ngaphandle kokuhlakaza isikhunta, okuzuzisa ukunciphisa isikhathi sokuphumula nokugcina izindleko zokuyilungisa. .

2. Uhlelo lokupholisa

-I-spiral cavity ukupholisa isiteshi samanzi kwenza umphumela wokupholisa ube namandla.

-Ishaneli yamanzi okupholisa echwebeni elinentambo kanye nesilayidi sithuthukisa umphumela wokupholisa.

-Ipuleti lokusabalalisa eliklanywe kahle eliphakathi nendawo, amanzi okupholisa angangeniswa ngokulinganayo endaweni ngayinye, futhi wonke ama-preforms angapholiswa ngokulinganayo nangokushesha.

3. Umgijimi oshisayo

- Umgijimi oshisayo onokusebenza okuhle kakhulu kwebhalansi uqinisekisa ukugeleza nokucindezela kwe-PET kuncibilika kuwo wonke ama-cavities afanayo.

-I-PET melt channeling inciphisa ukulahleka kwe-shear ne-IV futhi ivumela i-PET inyibilike ukuthi igeleze ngokulinganayo kuyo yonke imigodi.

- Ukusabalalisa ukushisa okuphezulu kugcina okuqukethwe kwe-acetaldehyde (AA) kuzo zonke izimbobo zizinzile.impahla

I-Custom Material 632: Ingcono kune-FS136 enokuqukethwe okuphezulu kwe-nickel nokuqukethwe kwe-chromium.

Ukuqina, ukumelana nokugqwala, nomphumela wokuba mhlophe kuyathuthukiswa ngokusobala.

Isisekelo sesikhunta senziwe nge-HRC 38 ~ 40 insimbi engagqwali noma i-P20 (i-pre-hardened).

2. Idizayini yesitaki yohlobo lwe-SelfLock

Ngaphambi kokuvala isikhunta, i-seam ehlukanisayo ivalwa endaweni yayo ngendandatho yokukhiya ukuze kuncishiswe ukuguga komugqa ohlukanisayo ohlangothini lwe-cavity kanye nohlangothi oluyinhloko, ngaleyo ndlela kunwebe impilo ye-burr-free yomugqa wokuhlukanisa.

Isingeniso Sokukhiqiza Isikhunta

| Uhlobo | Ubude(mm) | Ububanzi(mm) | Ubukhulu(mm) | Isisindo(kg) |

| 6 Umgodi | 650 | 270 | 490 | 600 |

| 8 Umgodi | 480 | 360 | 490 | 595 |

| 12 Umgodi | 610 | 360 | 490 | 755 |

| 16 Umgodi | 740 | 360 | 510 | 960 |

| 24 Umgodi | 790 | 500 | 510 | 1415 |

| 32 Umgodi | 800 | 580 | 510 | 1600 |

| 48 Umgodi | 1120 | 600 | 560 | 2640 |

| 64 Umgodi | 1380 | 600 | 610 | 3545 |

| 72 Umgodi | 1170 | 800 | 610 | 4010 |

| 96 Umgodi | 1230 | 960 | 610 | 5050 |

Idatha engenhla isekelwe ku-preform ye-16g enentamo ye-PCO.

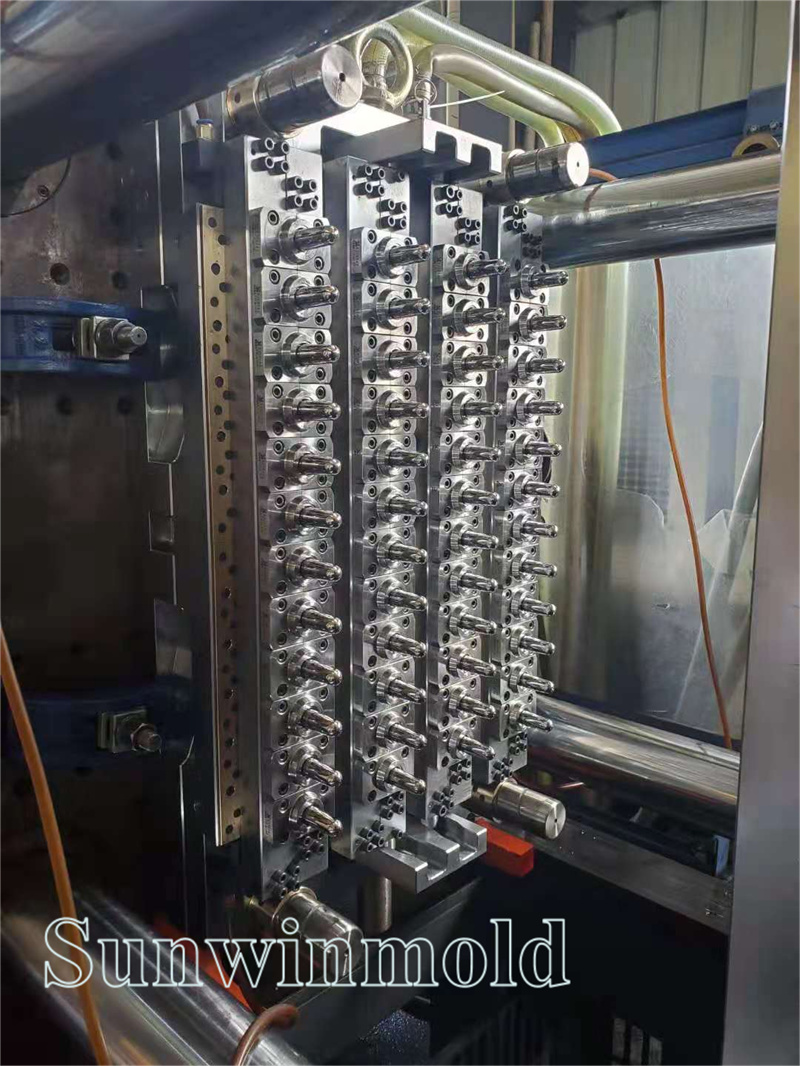

48-Cavity Air-Sealed PET Preform Mold

1. Okuhlangenwe nakho kochwepheshe kanye nobuchwepheshe emigodini yesikhunta ye-preform kusuka ku-1 kuya ku-96 cavities.

2. Isikhunta se-preform sisebenzisa isofthiwe ye-CAD ukuklama ukuma kwe-preform ngokusho kwebhodlela ukuqinisekisa ikhwalithi yokubumba yebhodlela.

3. Indwangu yokuvula intambo yesikhunta se-preform yenziwe ngensimbi ye-nitrided engenisiwe, eyenziwe ngokuvumelana nezindinganiso zamazwe ngamazwe, ngobulukhuni obukhulu, intambo ngayinye ifakwe umoya, futhi inempilo ende yesevisi ngaphandle kokuguqulwa.

4. I-preform mold core kanye ne-cavity yenziwe ngensimbi engagqwali, ehlala isikhathi eside.

5. Isikhunta se-preform samukela idizayini ethuthukisiwe yomgijimi oshisayo, ukuze i-cavity ngayinye ikwazi ukulawulwa ngokuzimele kwezinga lokushisa, ukufudumeza, futhi izinga lokushisa lifane.

6. Isikhunta sangaphambi kwesango esingasikiwe, ukonga abasebenzi nezinto zokusetshenziswa.

7. Izinga lokushisa lomsindo womgijimi oshisayo lilawulwa ngokwehlukana.(Ukuxazulula inkinga yokudweba mhlophe nocingo ngaphansi ngesikhathi senqubo yokukhiqiza).

8. Isikhunta se-preform yokuvala inaliti ye-valve: umongo ngamunye, i-cavity, ukuzivala okuzimele okuphindwe kabili, ukulinganisa okuguquguqukayo, ukunciphisa ukucaca, ukuqinisekisa ukugxila komkhiqizo, ukunemba okuphezulu.Isikhunta sinempilo ende yesevisi.

9. Ukusekela isampula nokudweba ukucubungula, hlinzeka ngokuthuthukiswa komkhiqizo omusha, isevisi yokumisa eyodwa yokucubungula ukubunjwa komjovo!

48-Cavity Air-Sealed PET Preform Mold

1. Izici zesikhunta:

1. Sisebenza ngokukhethekile ekukhiqizeni isikhunta se-valve inaliti, engadingi ukusika ngesandla.

2. Ukusetshenziswa kwesistimu yomgijimi oshisayo ethuthukisiwe kuqinisekisa ukuthi inani le-AA lomkhiqizo lisezingeni eliphansi.

3. Ukwakhiwa kweshaneli yamanzi okupholisa okunengqondo kuqinisa umphumela wokupholisa wesikhunta futhi kufinyeze ngempumelelo umjikelezo wokubumba umjovo.

2. Ukukhetha okubalulekile:

1. Izingxenye eziyinhloko zesikhunta zenziwe ngempahla ye-S136 engenisiwe (Sweden-Sabak).

2. Isisekelo sesikhunta sisebenzisa impahla ye-P20 engenisiwe kanye nokwelashwa kwe-electroplating, okuthuthukisa ukumelana nokubola kwesikhunta futhi kwandise impilo yesevisi yesikhunta.

3. Ukwelashwa kokushisa kwezingxenye kucutshungulwa esithandweni se-vacuum esingeniswe kusuka eJalimane, futhi ukuqina kwezingxenye kuqinisekisiwe ukuthi ku-HRC45 ° -48 °.

4. Izisetshenziswa ezithuthukisiwe zokucubungula:

Le nkampani yethule inani lamathuluzi omshini angenisiwe evela e-United States naseJapane, njengezikhungo zomshini, ama-CNC lathes, i-EDM, njll., ukuze kuqinisekiswe ukunemba komshini wezingxenye nokwenza izingxenye zibe nokushintshana okuhle., iphutha lesisindo lingaphansi kwe-0.3g, isikhunta se-2-5 singakhiqizwa ngomzuzu owodwa, futhi impilo yesevisi ingafinyelela izikhathi ezingu-2 zesikhunta.

24 Isikhunta se-Cavity Preform

Isakhiwo esisha sesikhunta se-preform esacwaningwa ngokuzimela futhi sathuthukiswa singaqeda ngokuphelele ukungalungi kwesikhunta esidlule, futhi singafinyelela ukunemba okuphezulu kanye nempilo ende yesikhunta, futhi singakwazi ukwenza ukulinganisa kwezingxenye ezihlukahlukene zesikhunta nokukhiqizwa okukhulu.Isikhunta sethu siqinisekisa ukuthi umehluko wokuqina odongeni weshubhu elingenalutho ungaphansi kuka-0.05mm, futhi iphutha lesisindo lingaphansi kuka-0.3g.Isikhunta se-2-5 singakhiqizwa ngomzuzu owodwa, futhi impilo yesevisi ingafinyelela izikhathi ezi-2 million.Isikhunta sinezimbobo eziningi ezingama-96.

12 Cavity PET Preform Mold

1. Kusetshenziswa umgodi wensimbi we-S136 ongenisiwe, umnyombo, nentamo enentambo kusetshenziswa, futhi ubulukhuni bokwelapha ukushisa bungafinyelela ku-HRC 48-50;wonke ama-formworks aphathwa ngokushisa ngobulukhuni be-HRC 30-35.

2. Ubuchwepheshe bokuklama isikhunta obuthuthukisiwe: Umgodi ngamunye uzikhiya ngokuzimela, usebenzisa i-SYATEM yesi-Japanese enembe kakhulu.Ukuqinisekisa isilinganiso esiphansi somzimba nokunemba komkhiqizo.Idayidi ngalinye linokufakwa okuyisipele kwezingxenye ezihlala isikhathi eside ezingashintshaniswa.Ukuze kuthuthukiswe futhi kuzuzwe ukusebenza kahle kokukhiqiza okuphezulu, sihlala siklama isistimu yokupholisa engcono kakhulu, futhi singafanisa umshini wokupholisa wesikhunta ngasinye.

3. Umgijimi oshisayo we-valve othuthukisiwe futhi onembile kanye nesilawuli sokushisa siqinisekisa ukwethembeka kokukhiqiza kanye nokudluliswa kokukhanya okuphezulu nokukhanya komkhiqizo.

4. Isikhunta esishelelayo senziwe ngethusi, umzimba webhodlela uhlangabezana nezinga lokuphepha kokudla, futhi ukuphila kwesikhunta kuqinisekisiwe ukuthi kunezikhathi ezingaphezu kwezigidi ezingu-3.1.Izici ze-Mold:

1. Sisebenza ngokukhethekile ekukhiqizeni isikhunta se-valve inaliti, engadingi ukusika ngesandla.

2. Ukusetshenziswa kwesistimu yomgijimi oshisayo ethuthukisiwe kuqinisekisa ukuthi inani le-AA lomkhiqizo lisezingeni eliphansi.

3. Ukwakhiwa kweshaneli yamanzi okupholisa okunengqondo kuqinisa umphumela wokupholisa wesikhunta futhi kufinyeze ngempumelelo umjikelezo wokubumba umjovo.